In lithography and metrology processes, the precise alignment and filtering of the beam is directly related to the wafer´s quality. This reduces the moving mass significantly compared to stage attached mirrors.īeam aperture and filter positioning | Attocube Systems AG

The miniaturized sensor heads can be integrated directly into the wafer stage. Attocube´s laser interferometer IDS3010 enables metrology tools to achieve the required precision at nanometer range over long distances up to 5 meters with a target velocity of up to 2 m/s. These requirements can only be achieved by utilizing ultra-precise sensors to control the wafer stage’s movements. Furthermore, single digit nanometer precision is required to ensure dense circuit patterns. Wafer stages need to perform ever larger and faster movements to increase throughput of the production process. The miniaturized sensor heads allow for various measurement points on one wafer to detect multi-dimensional deformations and also work under extreme environments such as vacuum or clean room conditions.ĭynamic motion control of wager stages | Attocube Systems AG Attocube´s laser interferometer IDS3010 is capable of measuring directly on the wafer to capture such deformations in nanometer range. To reduce these deformations a nanoprecise and contactless detection is required. the movement of wafer stages working with magnetic levitation deforms the flat surface of the plate. These could cause elastic or plastic deformations. Planarity detection of wafers | Attocube Systems AGĭuring lithography and metrology processes the wafer is exposed to extreme environments, fast motions and multi-dimensional forces.

Dixi polytool birkenfeld plus#

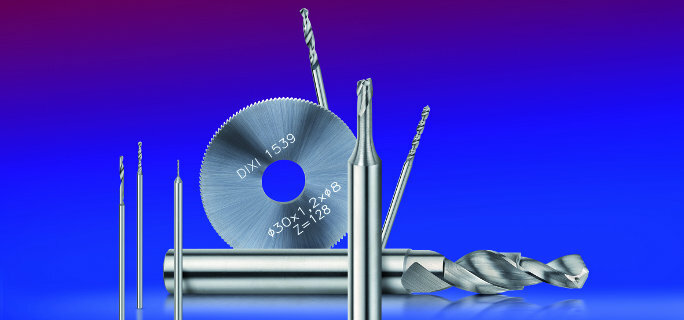

We can also offer special offers based on the COOL PLUS concept. The COOL PLUS concept consists of an extensive range of standard cutters.

This reduces the cutting forces on the tool by up to 50% which gives a significant difference in tool life. With our COOL PLUS concept we accelerate the coolant with high precision and cool the cutting edges. Partly due to the unique cooling ring, our precision is optimally cooled. Grinding automation | RVS Finish & RVS Clean | Stand 385 DIXI COOL PLUS concept Polytool | DIXI PolytoolĭIXI Polytool presents its innovative DIXI COOL PLUS concept for micro and high-performance milling. The right mix of man and machine in assembly processes | Tegema B.V. Grade 2 coolant and cleaning installations | Oude Reimer | Stand 446Įdwards’ APG200 Vacuum Pirani Gauge | Edwards Vacuum | Stand 375Įdwards’ nEXT turbomolecular vacuum pumps| Edwards Vacuum | Stand 375Įdwards’ nXRI multi-stage roots vacuum pumps | Edwards Vacuum | Stand 375 Ultra precise position tracking in photolithography | Attocube Systems AG | Stand 376 Laser beam adjustment in metrology and inspection tools | Stand 376 Planarity detection of wafers | Attocube Systems AG | Stand 376ĭynamic motion control of wager stages | Attocube Systems AG | Stand 376īeam aperture and filter positioning | Attocube Systems AG | Stand 376 We would like to highlight a number of innovations for you:ĭIXI COOL PLUS concept Polytool | DXI Polytool | Stand 252 Discover all trends during the Precision Fair. This is due to increasing precision and far-reaching miniaturization. Precision technology will become even more important for industry in the coming years.

Dixi polytool birkenfeld iso#

elaborated a system of certified management according the standards ISO 9001 and ISO 14001.įor several years, DIXI Polytool SA has decided to use only 100% recycled paper, natural colouring ink for our catalogues and flyers.įurthermore, we are proud to be a precursor by using green energy for the maintenance of the building and the production, since January 2015.A world without precision technology is almost unimaginable. With the introduction of the Lean Project, back in 2013, and the heavy investments in the production, our efforts are also focused on supporting our (customers and) 250 co-workers.Įager to guarantee the quality of its products while preserving the environment, DIXI Polytool S.A. In 2014, the premises have been completely renovated and enlarged. The company is based in Le Locle since 1946. is specialized in the production of tungsten carbide and diamond cutting tools as well as precision reamers. Manufacturing programme / Services providedĭIXI Polytool S.A.

Economic activities (official classification NOGA)

0 kommentar(er)

0 kommentar(er)